Infrastructure

Injection Molding Machine

Injection Molding Machine available in Plant as per below Specification

All Machine are brand new brought from Toshiba and Haitian.

- Machine Capacity- 60 Ton to 350 Ton

- Part weight capacity- 2 gram to 550 gram

- All machine are Bio metallic ready for up to 45% GF.

VMC Machine

We have highly precise VMC, Manufactured by Haas( A unit of Phillips) Made in USA.

Key feature in VF2 model. We have Total 9 VF2 and 1 VF4 size Machine available in our premise.

-10,000 RPM Inline direct drive spindle.

-30+1 side mount tool changer.

-762 X 406 X 508 (XYZ) axis travel in VF2

-1270 X 508 X 635 (XYZ) Axis travel in VF4

-Max. Torque 122 Nm@2000 RPM.

-914 X 356 Table size.

25.4 mm/m cutting speed

Haas 6” chuck CNC Turning Mil [ST10 Y]

The Haas ST Series high-performance turning centres were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability.

The ST-10 has an extra-small footprint, yet provides a generous work envelope. This machine offers the best performance for the money – the best value – in its class.

- Extra-small footprint

- Work in X & Y both axis

- High rpm and rapid speeds

- Ideal for high-volume, high-production environments

- Made in the USA

Haas 8” chuck CNC Turning Mil [ST15 Y]

he Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability.

The ST-15Y is an extra-small footprint, big-bore lathe with a generous work envelope. The addition of Y-axis and live tooling allows milling, drilling, and tapping for increased machine capabilities. This machine offers the best performance for the money – the best value – in its class.

- Extra-small footprint

- Big-bore spindle

- Y-axis milling, drilling, and tapping

- High rpm and rapid speeds

- Made in the USA

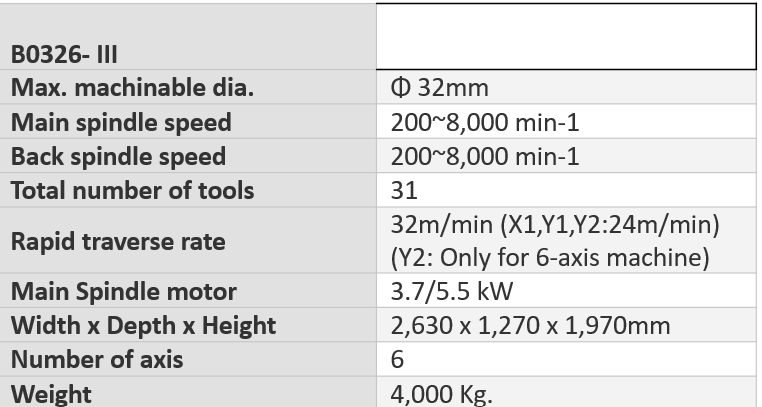

CNC Precision Automatic Lathe [ Manufactured by Tsugami Japan ]

Completely simultaneous processings are possible between main and back spindles for complex machining thanks to the Y-axis of back tool post. (6-axis machine).

Modular type live tools can be arranged onto the rear tool post and the back tool post. The suitable tools and position can be selected according to the workpiece.

Optional direct-drive rotary guide bushing provides highspeed and accurate machining.

Guide-bush type or guide-bushless type is selectable (L type is exclusive guide-bushless machine

Software is fully installed as standard for simplified operation.

Automatic programming software is prepared as standard

Optional oscillation cutting function is available for breaking swarf into pieces.

Series: Neo+ | Neo 2050 [ Total 2 machine]

BFW’s HTL series of Neo turning centers are designed with Unrivalled Rigidity, High Productivity & Reliability to enhance unmatched flexibility for wide variety of part configurations. Developed to meet the requirements of job shops as well as mass production.

- Enabled for Automation

- High precision ball screws for X & Z axes

Orbitur– Compact Turning Centre [ Total 7 machine]

Series: Orbitur | Orbitur+

BFW’s HTL series of Orbitur turning centers are designed with Unrivalled Rigidity, High Productivity to enhance unmatched flexibility for wide variety of part configurations. Developed to meet the requirements of job shops as well as mass production.

- Compact foot print, Ideal for line setup

- Precision LM Guides for X & Z axes

- High precision ball screws for X & Z axes

- Enabled for Automation

- Innovative design for tramp oil separation for lesser running cost

Conventional Tool Room

Lathe Machine – 6 ft , 8 ft , 12 ft

Surface Grinder- 10 X 20 inch, 8 X 16 inch

Milling with DRO- 1 mtr

Center less Grinder- 1mtr

Drill Machine- 1 No’s

Band saw- 1 No’s

Spot Welding- 1 No’s

DG set- 150 KVA & 500 KVA

Air Compressor – up to 120 CFM

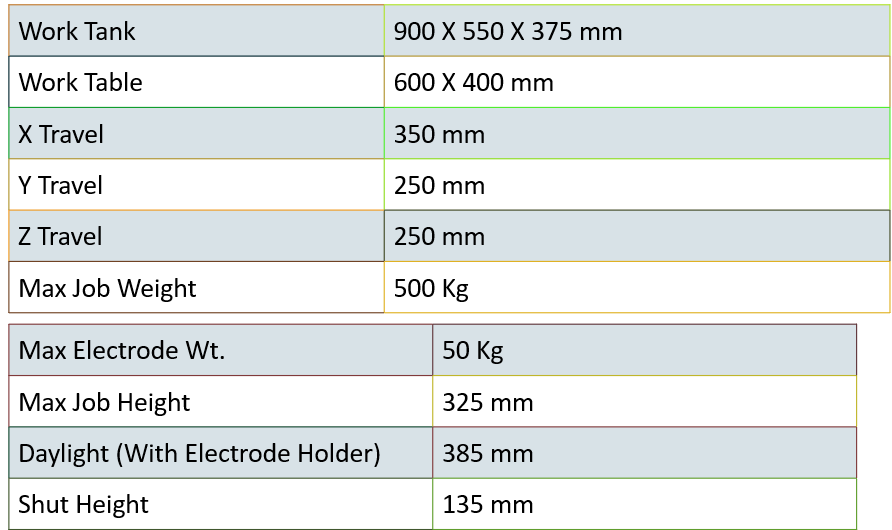

Wire Cut Machine [ Electronica make ]

oAbility to work on Hardened materials.

oComplex profile capability.

oBlind cavities & Sharp corners possible

oLow Cutting forces & hence low work holding forces

oEliminates Mechanical distortion

oBurr free cutting possible

oMachining of Tungsten carbide is possible

EDM Machine- [S 50| ZNC]

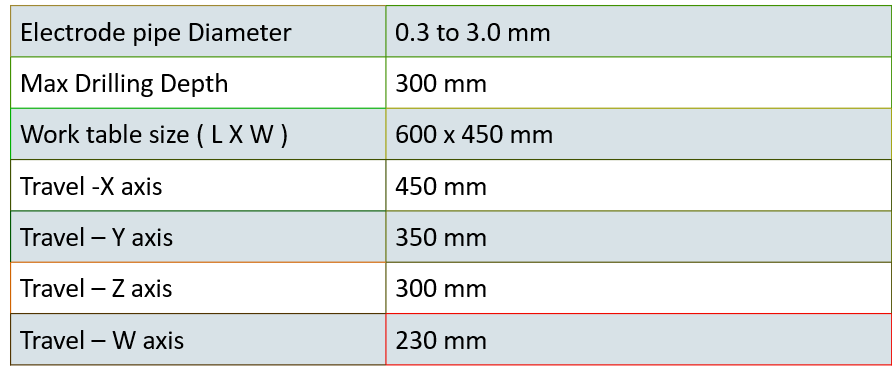

CNC EDM Drill

- CMM [ coordinate measurement machine ]

- Make- Carl Zeiss

- Model- 7/10/6 RDS XXT probe system

- Table size – 700 X 1000 X 600 [mm]

- Cad cam comparison available in software.

- Automatic probe changer

- Touch trigger probing system